Hướng dẫn lắp đầu báo khói địa chỉ FSP-951, FSP-851

Hướng dẫn lắp đặt đầu báo khói địa chỉ FSP-951, FSP-851

SPECIFICATIONS

Base Diameter: 4.0 inches (10.2cm)

Base Height: .74 inches (18.8 mm)

Operating Temperature: Refer to applicable sensor Operating Temperature Range using the Base/Sensor Cross Reference Chart at systemsensor.com

Electrical Ratings – includes base and detector

Operating Voltage: 15 to 32 VDC

Standby Current: 150µA

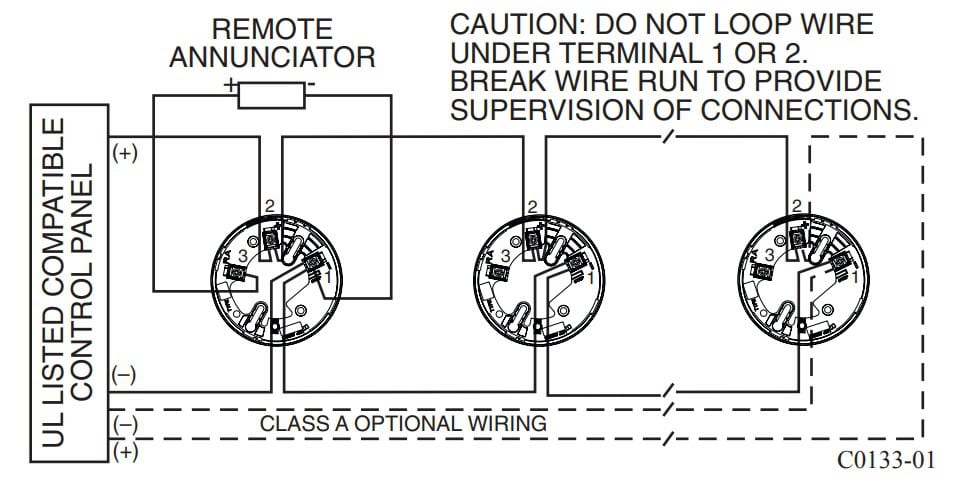

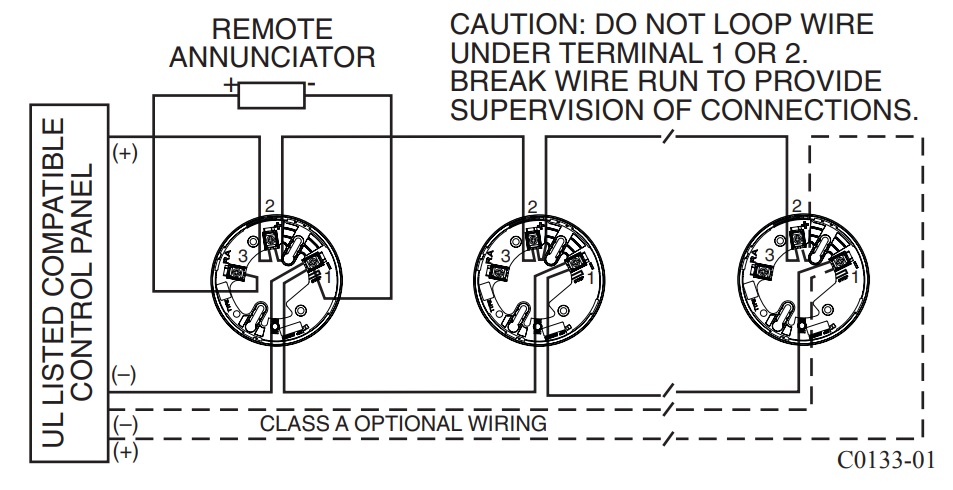

Các chân của để B501 với các đầu nối vít được cung cấp cho nguồn (+) và (-) , kết nối và giao tiếp diễn ra qua đường dây nguồn (+) và (-)

Cách đấu nối cho đế đầu báo và kết nối với nhiều đầu báo.

Tham khảo sản phẩm

BEFORE INSTALLING

Please read the System Smoke Detectors Application Guide, which provides

detailed information on detector spacing, placement, zoning, wiring, and special applications. Copies of this application guide are available from System

Sensor. NFPA 72 guidelines should be observed.

NOTICE: This manual should be left with the owner/user of this equipment.

IMPORTANT: The detector used with this base must be tested and maintained

regularly following NFPA 72 requirements. The detector should be cleaned at

least once a year.

For signal wiring (the wiring between interconnected detectors and modules),

it is recommended that the wiring be no smaller than 18 AWG (0.823 square

mm). Wire sizes up to 12 AWG (3.31 square mm) may be used with the base.

Alarm system control panels have specifications for allowable loop resistance.

Consult the control panel specifications for the total loop resistance allowed

before wiring the detector loops.

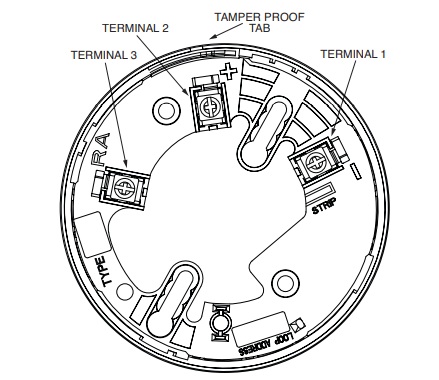

Make wiring connections by stripping about 3⁄8 inch (10 mm) of insulation

from the wire end (use strip gauge molded in base). Then slide the wire under

the clamping plate and tighten the clamping plate screw. Do not loop the wire

under the clamping plate. (see Figure 3)

Check the zone wiring of all bases in the system before installing the detectors. This includes checking the wiring for continuity, correct polarity, ground

fault testing and performing a dielectric test.

The base includes an area for recording the zone, address, and type of detector to be installed at that location. This information is useful for setting the

detector head address and for verification of the detector type required for

that location.

Once all detector bases have been wired and mounted, and the loop wiring

has been checked, the detector heads may be installed in the bases.